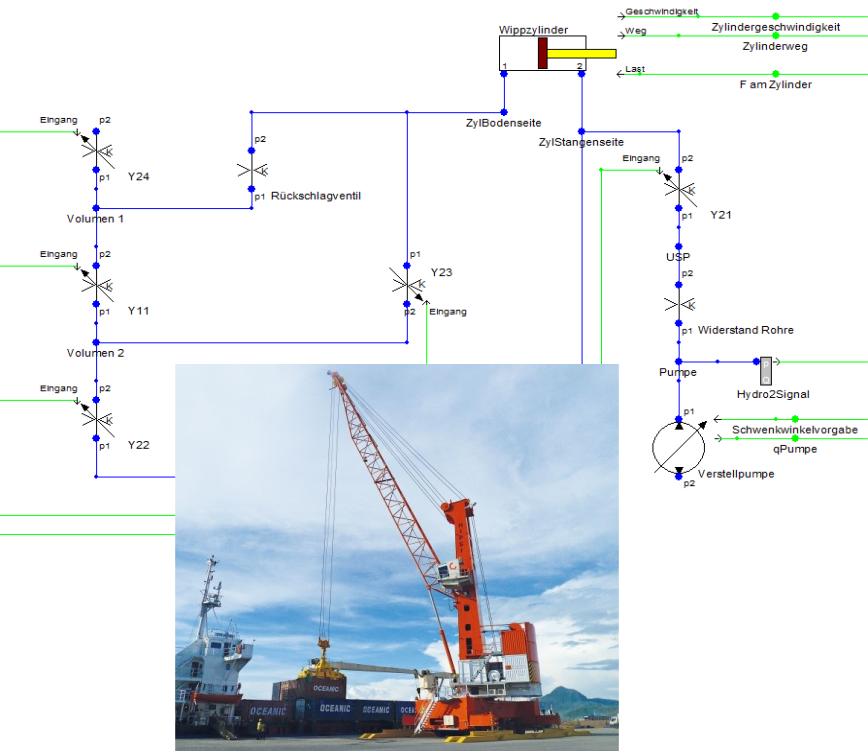

Energy-efficient Luffing Gear Hydraulics for Mobile Harbour Cranes

Challenge

Automatically operated hydraulic luffing jibs of mobile harbour cranes consume large amounts of fuel.

Conditions

- Due to the high handling capacity of luffing gear hydraulics, high dynamic forces act during the boom movement.

- The luffing gear hydraulic system is the main energy consumer of the mobile harbour crane.

- Changes to this system are often time-consuming and cost-intensive, checking of changes is typically based on performing new measurements on the actual system.

Scope

To increase energetic efficiency and reduce fuel consumption of mobile harbour cranes.

Task

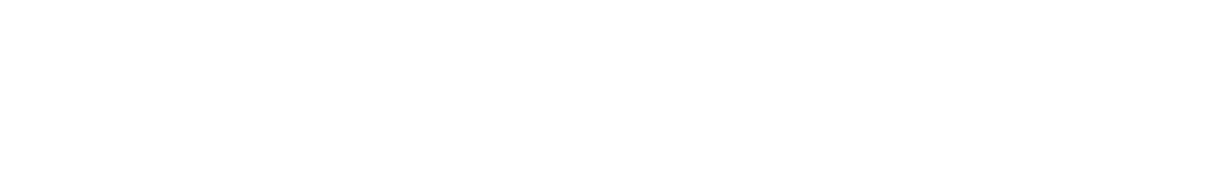

- Development of a new hydraulic system for the luffing cylinder to reduce energy consumption

- Investigation of the requirements on the components for a typical load cycle

- Comparison of the new hydraulic system with a simulation model of the previous hydraulic system in terms of energy efficiency

Solution

- Derivation of the kinematic and dynamic relations for the calculation of the force acting on the cylinder

- Development of control strategies

- Incorporation of a representative load cycle into both simulation models

- Evaluation of component requirements

- Comparison of energy efficiency

Detailed Information

Detailed questions regarding the above-mentioned projects or possible solutions to specific problems will be answered directly by our engineering team.